Despite being a small family business, Helid pays continuous attention to process optimization and management technology innovation, in order to guarantee its customers a certified, complete supply and in compliance with the agreed delivery times.

Our organization allows us to manage single pieces or small/medium sized lots with the same procedure: each production phase (carried out internally or externally at our qualified suppliers) is computerized according to the Industry 4.0 standard and the progress of the order production is quickly available in real-time

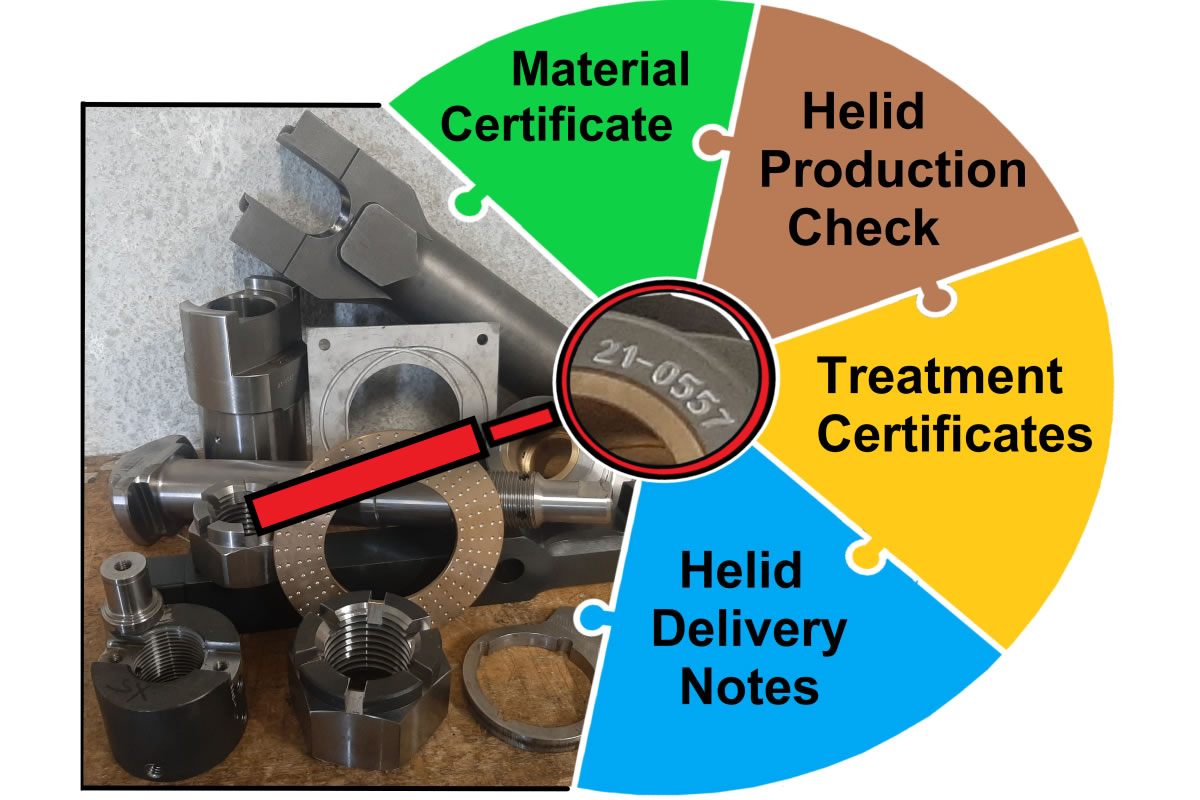

From the order number (physically marked on each piece produced) you can easily trace its entire history:

- Material used + certificate of the same with casting, material type, initial hardness, …

- When, on which machinery and by whom each internal production phase was performed

- When and by whom all external processing was performed (eg: remediation, cementation, ultrasound tests, magnetic powder tests, tensile tests, destructive tests, ...) + any certificate of conformity produced by the supplier

- When, how many pieces and to which customer they were supplied

At the customer's request, Helid can provide details of the production orders included in its sales documents and related certificates

Quality at an affordable price

Our experience and the optimization of our twist lock production process allow us to maintain competitive prices for quality products, certified, tested and registered for identification and traceability

Delivery speed

Thanks to the use of printed material (in 34 NiCrMo6) and already "ultrasonic" we reduce production times and can guarantee fast delivery times.

Flexibility

Our network of qualified suppliers allows us to meet the customer's needs, providing a product complete with all the required tests or treatments (magnetic powder testing, tensile test, destructive test, hardening, ...)

In compliance with the Machinery Directive 2006/42/CE, we can mark our twist locks CE and produce the relevant certificate.

The safe working load (SWL=Safe Working Load) is specified both on the twist lock and on the CE certificate of conformity. In defining this value, Helid complied with the European standard UNI EN 13155:

Creating a prototype for each of the most common twist locks (tested with a tensile test at a load equal to three times the declared SWL value)

OR

By sampling each production lot with a load equal to double the declared SWL value

We have been ISO 9001-2015 certified since 2020: the punctual application of its standards is a guarantee for the entire production cycle.